The Key to Precision in the Einstein Telescope

What is the Einstein Telescope?

The Einstein Telescope is an advanced observatory designed to detect gravitational waves. These waves, predicted by Einstein’s theory of general relativity, offer insights into the most extreme phenomena in the universe. These include the formation of black holes, the structure of neutron stars, and the state of the universe shortly after the Big Bang. The proposed location for the telescope is an underground tunnel system near the Dutch-German-Belgian border, though the Italian island of Sardinia is also under consideration.

Why Vibration-Free Cooling?

While the telescope’s location is yet to be finalized, significant progress is being made in developing the necessary technology and components. One of the major challenges is vibration-free cooling. To accurately capture gravitational waves, the thin layers on the mirrors of the Einstein Telescope must be cooled without vibrations. Even the slightest disturbance can compromise the measurements, introducing noise — a scenario to avoid at all costs.

From Spacecraft to Telescope

Few people know that Cooll originated from earlier development work for a planned space mission initiated at the University of Twente in 2003. Under contract with ESA, we developed a vibration-free cooler capable of cooling to -270°C without moving parts (and without maintenance). This foundational technology inspired our heat pump in 2009. When we learned that the Einstein Telescope team needed a vibration-free cooler, we immediately realized we could deliver the core of such a system. Together with Demcon kryoz and the University of Twente, we joined the project. Our proposal was quickly accepted, and we became one of the first companies involved. Starting January 2024, we will collaboratively develop this innovative cooling system.

Einstein Telescope setup

Project team inspection at the ETpathfinder facility

Einstein Telescope setup

Close up of a cooling chamber at the ETpathfinder facility

Einstein Telescope setup

Project team inspection at the ETpathfinder facility

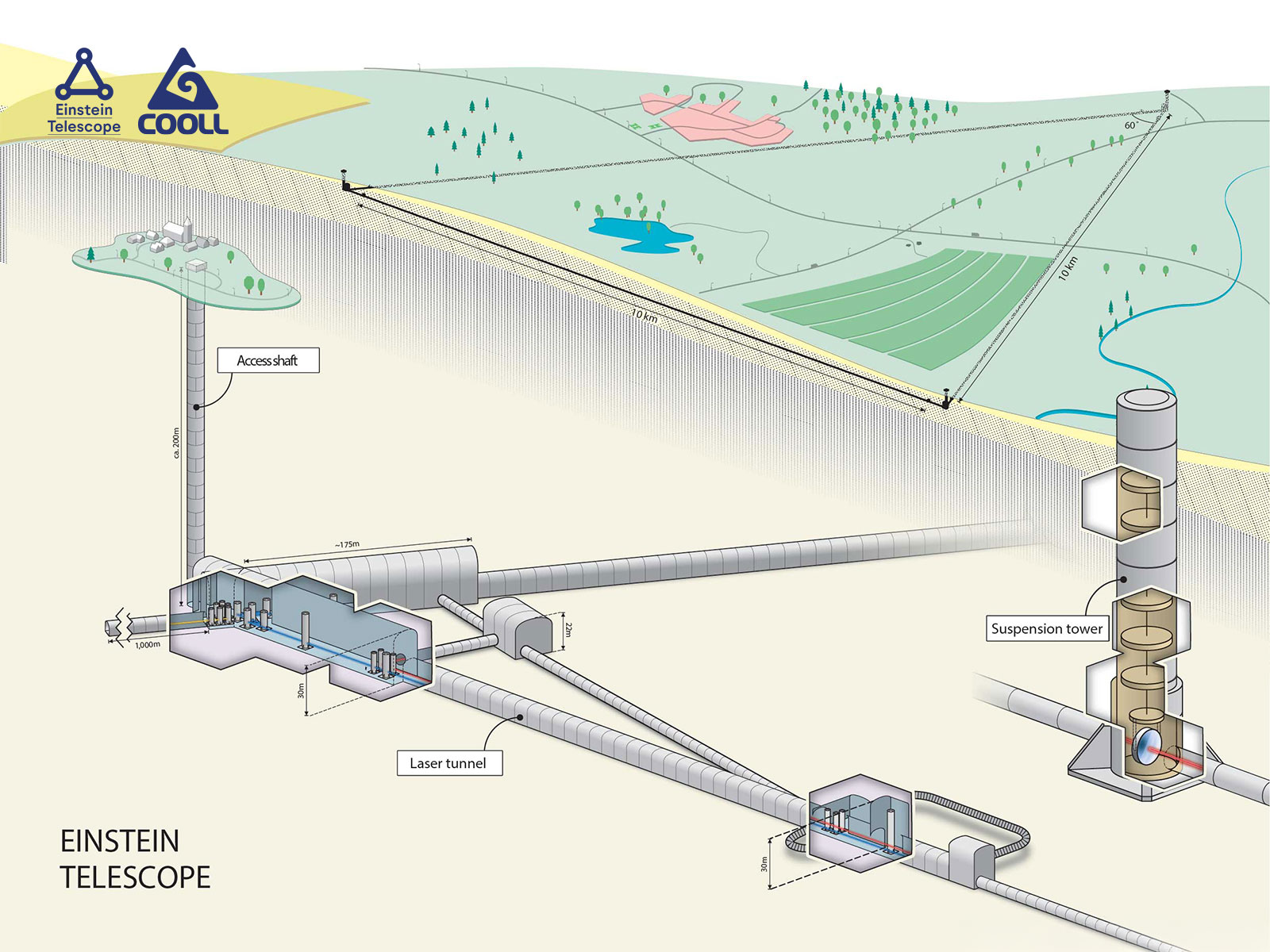

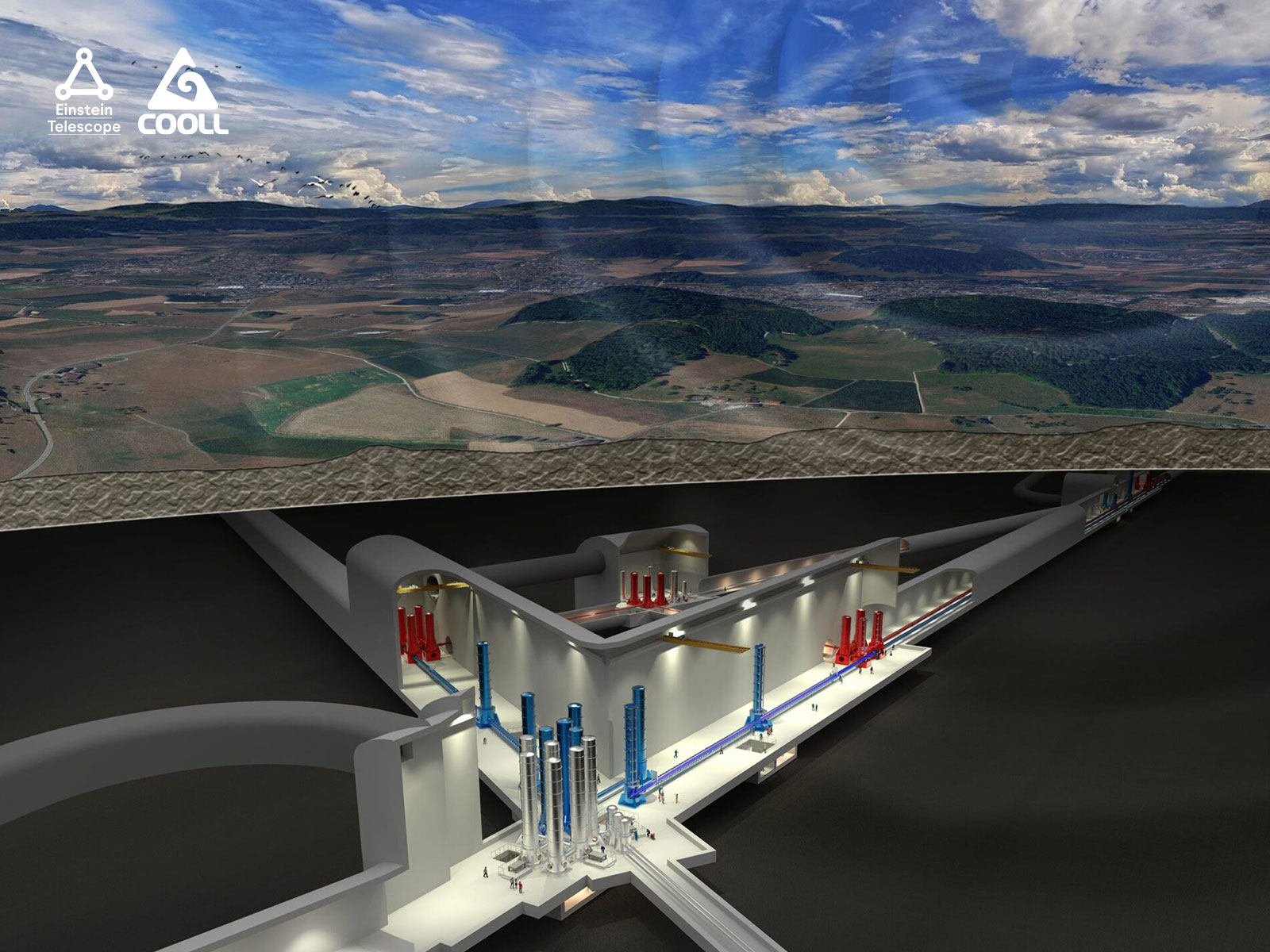

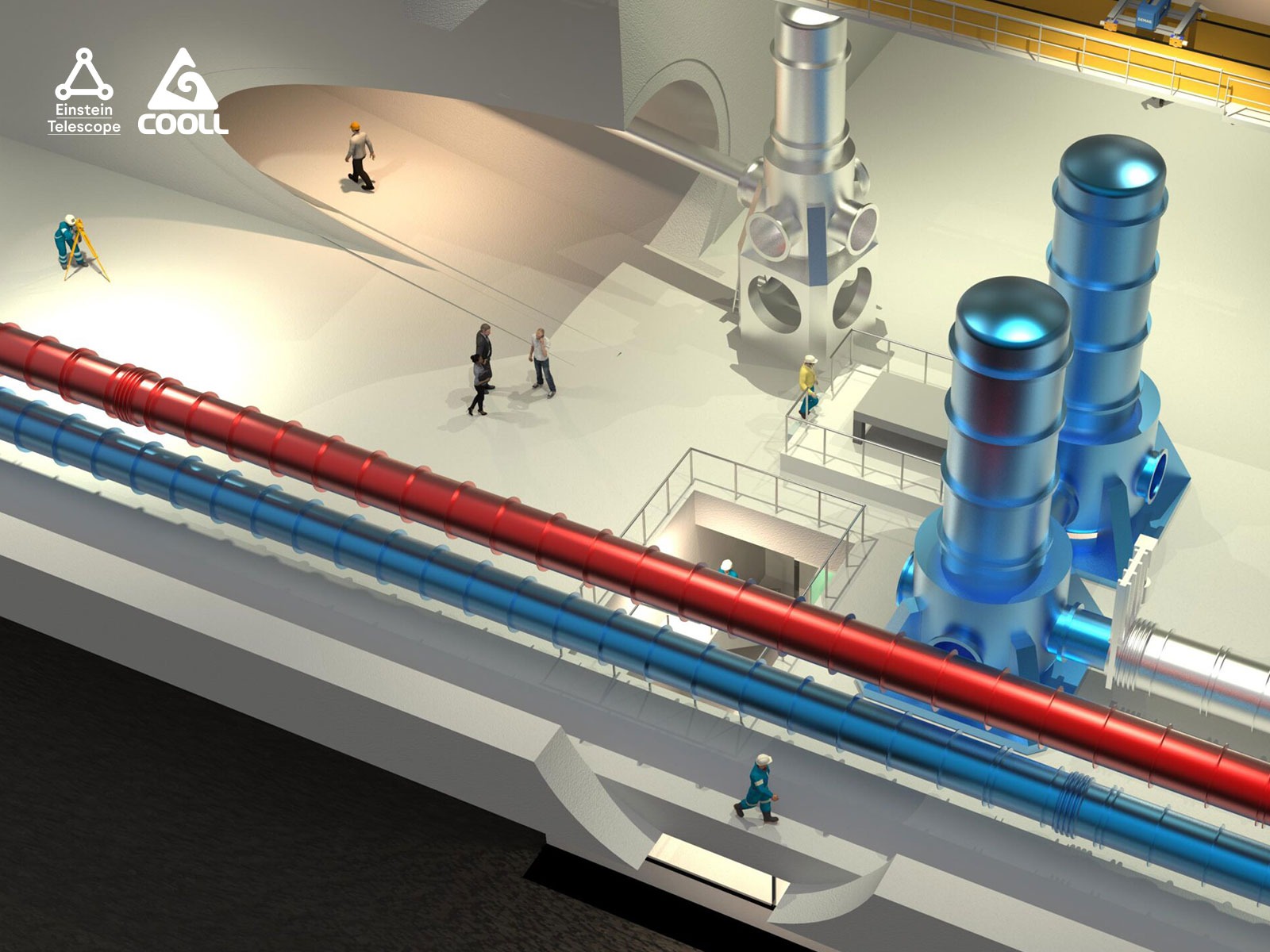

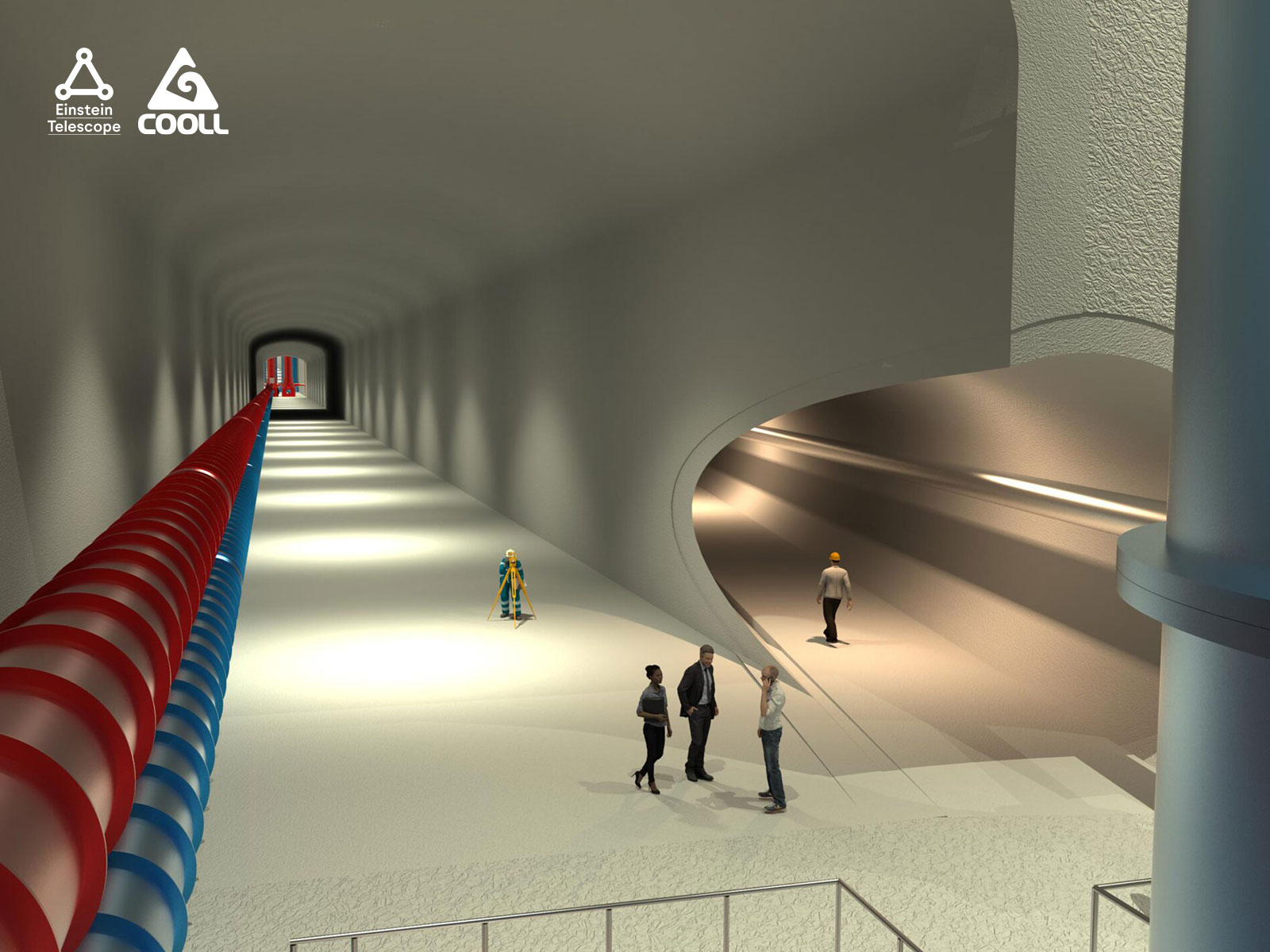

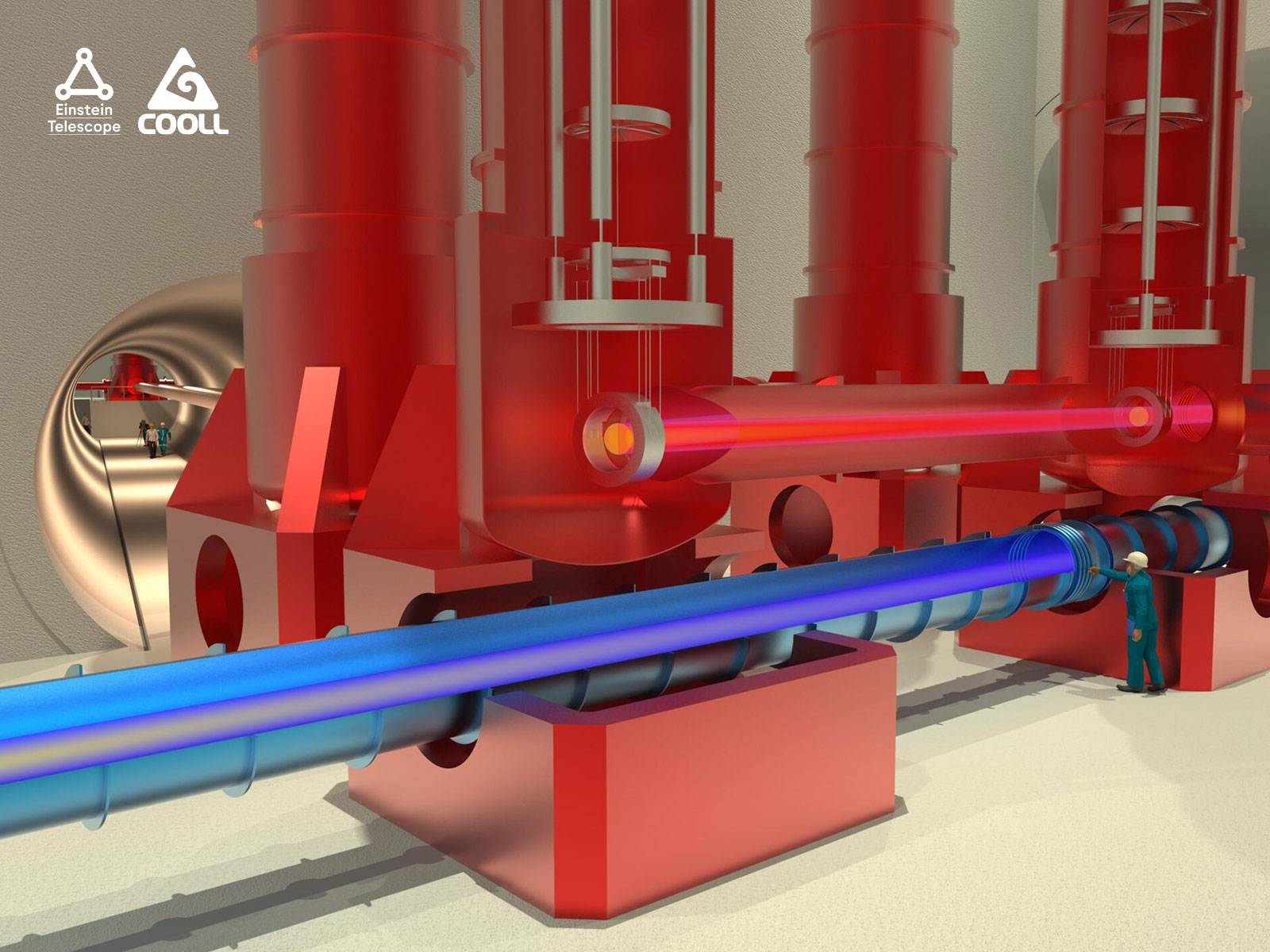

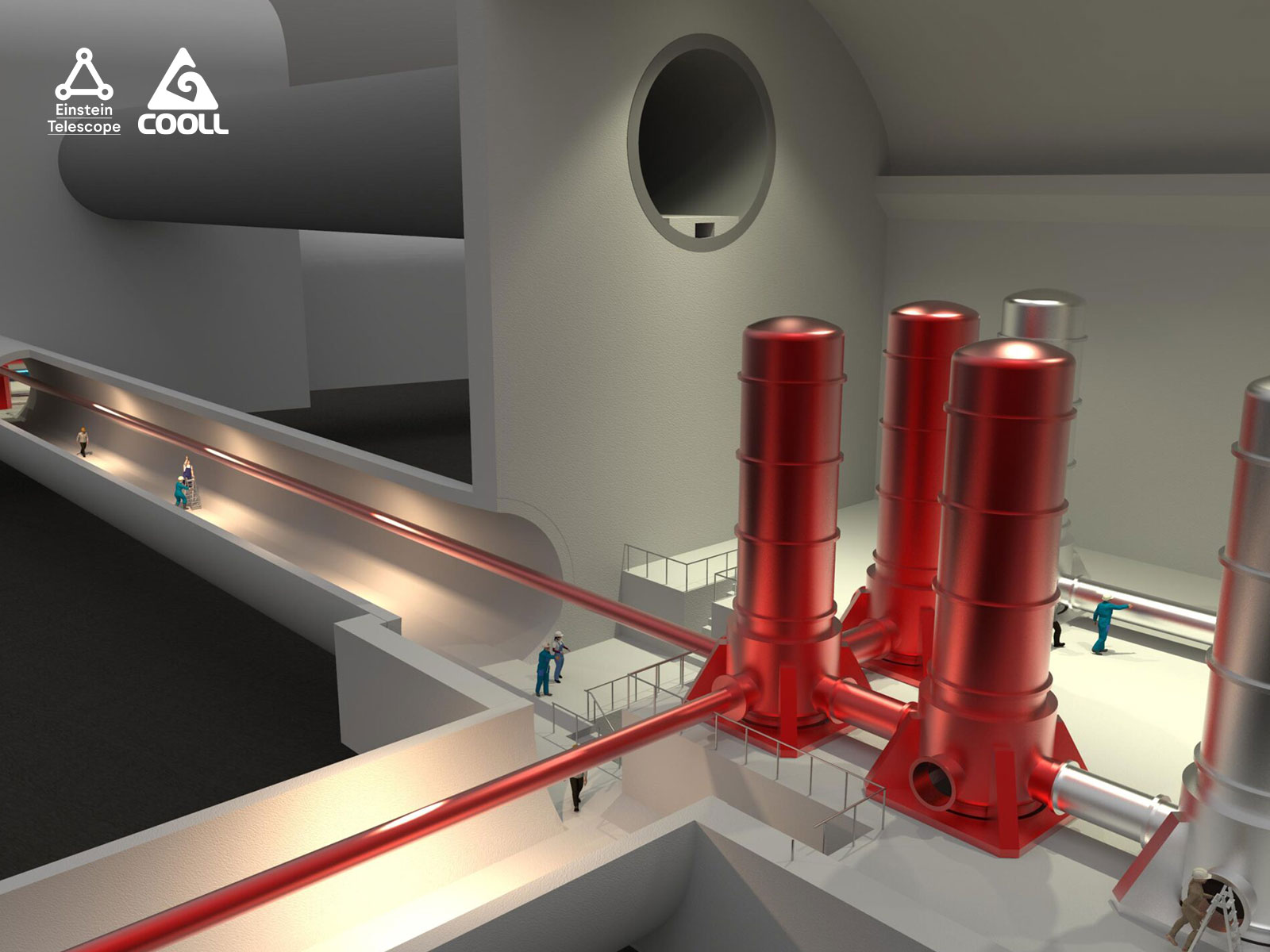

Einstein Telescope in 3D by Marco Kraan/Nikhef

Source: einsteintelescope-emr.eu

Einstein Telescope in 3D by Marco Kraan/Nikhef

Source: einsteintelescope-emr.eu

Einstein Telescope in 3D by Marco Kraan/Nikhef

Source: einsteintelescope-emr.eu

Einstein Telescope in 3D by Marco Kraan/Nikhef

Source: einsteintelescope-emr.eu

The Strength of the Consortium

Cryogenic Cooling by Demcon kryoz

In scientific technology for space applications, everything must be better, more robust, and safer than standard industrial solutions. Demcon kryoz, with years of experience designing and building small vibration-free cryogenic cooling systems, is a logical and strong partner. However, this project demands a significant step forward. The primary challenges lie in achieving extremely low vibration levels, combined with the required cooling capacity and ultra-low temperatures. Demcon kryoz, as a major industrial player, authored the project proposal and coordinates the entire effort.

Adsorption Technology by Cooll

The cooling system operates on a closed cycle powered by a compressor that circulates gas for years. The cycle is based on adsorption (with a “D”), made possible using high-quality activated carbon, the core of this technology. Cooll manufactures this activated carbon in-house. The system uses helium, hydrogen, and neon as (non-polluting) cryogenic refrigerants. Notably, our compressor contains no motors, rotating shafts or membranes that could possibly cause any vibrations.

Testing at the University of Twente

The cooling system for the Einstein Telescope is tested in a setup at the University of Twente. This involves a large vacuum chamber initially cooled with liquid nitrogen. Subsequently, neon, hydrogen, and helium further lower the compressor’s temperature to -265°C (8 Kelvin), precisely meeting the project’s requirements. The University of Twente contributes with its extensive cryogenic expertise, gained from various Big Science projects.

National Growth Fund Subsidy

The final partners worth mentioning are LIOF and the National Growth Fund. The guidance of LIOF and subsidy of the Ministry of Economic Affairs enable us to work on this prestigious project through 2026. By late 2025, we aim to complete the final product. We are on schedule, making this goal achievable. This is a unique opportunity to showcase the advanced capabilities of the Dutch cryogenic industry and our readiness to tackle large-scale projects.

Opportunities for Industry and the Built Environment

Cooll’s adsorption heat pump leverages the core technology mentioned above, but reverses the process to provide heating instead of cooling. The absence of noise and vibrations is a significant advantage, with promising potential for both industrial and residential applications.